Understanding China Plastic Injection Molds: The Backbone of Modern Manufacturing

Plastic injection molding is a crucial process in the contemporary manufacturing landscape, known for its efficiency and capability to produce complex and precise components. Among the global leaders in this industry is China, where China plastic injection molds have become synonymous with quality, innovation, and affordability. This article explores the various facets of plastic injection molds, their applications, benefits, and why manufacturers worldwide lean towards Chinese expertise. By the end of this comprehensive exploration, you will understand how China stands at the forefront of this vital sector.

The Basics of Plastic Injection Molding

At its core, plastic injection molding involves creating parts by injecting molten plastic into a mold. Once cooled, the mold is removed, leaving a finished product. This method is widely favored for several reasons:

- High Efficiency: The process allows for the rapid manufacturing of large quantities of parts.

- Precision and Detail: Modern molds can create highly detailed components with tight tolerances.

- Material Versatility: Various plastics can be used, offering different attributes such as durability, flexibility, or aesthetic appeal.

Why Choose China for Plastic Injection Molds?

China's dominance in the plastic injection mold market stems from several key advantages:

Cost-Effectiveness

Lower Labor Costs: The labor market in China typically provides lower costs for skilled labor, allowing for significant savings in the overall production process.

Economies of Scale: Chinese manufacturers often produce molds in large quantities, reducing the cost per unit significantly.

Advanced Technology

China has heavily invested in modernizing its manufacturing facilities, adopting the latest technologies:

- CAD/CAM Systems: Innovative software aids in designing and manufacturing precise molds.

- Robotics: Automation in production lines enhances efficiency and consistency.

- Quality Control: Advanced inspection technologies ensure that every mold meets stringent quality standards.

Wide Range of Mold Types

Chinese manufacturers produce a variety of molds to cater to diverse industry needs:

- Cavity Molds: Ideal for producing multiple identical parts.

- Core Molds: Used for creating hollow components.

- Hot Runner Molds: Enhance efficiency by staying heated, reducing waste and cycle times.

- Two-Shot Molds: Allow for the combination of different materials or colors in a single mold.

The Importance of Quality in Plastic Injection Molds

Quality control is paramount in the process of plastic injection molding. Poor quality molds can lead to significant production delays, increased costs, and unsatisfactory final products. Manufacturers in China prioritize several aspects of quality:

Material Selection

The choice of raw materials is critical. High-quality steel is often used for mold construction, providing durability and longevity. Furthermore, the use of environmentally friendly plastics is becoming increasingly popular as global demand for sustainable practices rises.

Precision Engineering

Every detail matters in mold design. Chinese manufacturers employ skilled engineers who utilize advanced software for precision modeling to ensure that molds fit perfectly and produce accurate components. This reduces the need for post-production adjustments, saving time and resources.

Testing and Prototyping

Before full-scale production begins, prototypes are created to test the mold's effectiveness. This phase is essential for identifying any potential issues, ensuring the final product meets customer specifications.

Applications of China Plastic Injection Molds

Plastic injection molds from China are utilized across numerous industries, showcasing their versatility and importance:

Automotive Industry

In the automotive sector, China plastic injection molds are used to create dashboard components, interior fittings, and even exterior parts. The ability to produce lightweight yet durable parts is critical in modern vehicle design, and Chinese manufacturers excel in this area.

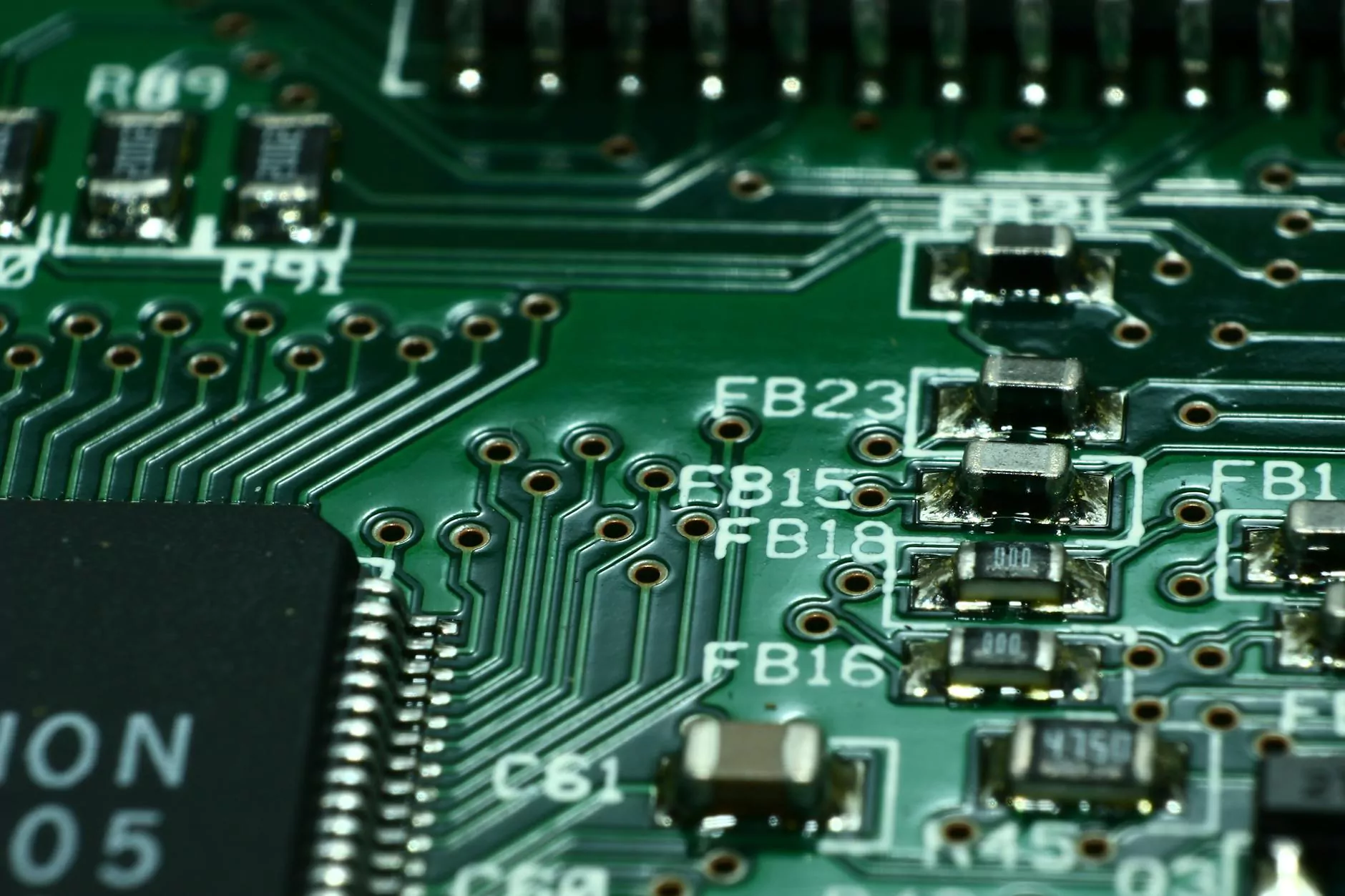

Consumer Electronics

From smartphone casings to intricate internal components of electronics, the consumer electronics industry relies heavily on quality injection molds. The rapid pace of innovation in technology requires manufacturers to work closely with mold producers to maintain competitive edge.

Medical Devices

China's plastic injection molds are instrumental in producing medical devices that meet strict regulatory requirements. Products such as syringes, casings for electronic medical devices, and various lab equipment showcase the precision and reliability of Chinese molds.

Toys and Household Goods

The toy industry often uses vibrant, safe plastics to create engaging products for children. Chinese manufacturers are champions in delivering colorful, creative designs that are both safe and durable, meeting global safety standards.

Future Trends in Plastic Injection Molding

The future of plastic injection molding in China looks promising. Emerging trends include:

Sustainability Practices

With global awareness of environmental issues rising, Chinese manufacturers are increasingly focusing on sustainable practices, including:

- Biodegradable Plastics: Using materials that minimize environmental impact.

- Recycling Initiatives: Implementing programs to recycle scrap plastics generated during production.

Advanced Technology Integration

China is actively integrating cutting-edge technologies such as:

- 3D Printing: For rapid prototyping and complex mold designs.

- IoT Devices: To monitor production processes and enhance efficiency.

Global Market Expansion

As demand for quality and cost-effective molds rises, Chinese manufacturers are looking to expand their markets. Developing strong partnerships with international buyers and adapting to global standards will be key in maintaining their competitive edge.

Choosing the Right Manufacturer in China

Selecting the right China plastic injection mold manufacturer requires careful consideration. Here are some factors to keep in mind:

Experience and Reputation

Look for manufacturers with a proven track record in the industry. Client testimonials and case studies can provide insight into their reliability and quality of work.

Production Capabilities

Evaluate the manufacturer's facilities and technologies. A company that invests in state-of-the-art technology is likely to produce higher quality molds.

Communication and Support

Effective communication is critical. The ability to discuss project specifications and concerns in real-time can help ensure that the final product meets expectations.

After-Sales Service

Consider manufacturers that offer after-sales support, including maintenance and modification services for molds. This can significantly extend the lifespan of the molds and maintain production efficiency.

Conclusion: The Future of China Plastic Injection Molds

In conclusion, China plastic injection molds play a pivotal role in the manufacturing landscape. Their efficiency, precision, and versatility make them essential across many sectors, from automotive to medical. As the demand for quality and sustainable practices increases, Chinese manufacturers are well-positioning themselves to meet future challenges.

The ongoing innovation and investment in technology and eco-friendly practices ensure that China will continue to lead the plastic injection mold industry for years to come. For businesses looking to enhance their production capabilities, partnering with reputable Chinese mold manufacturers can be a strategic decision that leads to improved quality and greater profitability.

For quality plastic injection molds, consider visiting DeepMould.net, a leading manufacturer dedicated to excellence in mold production.